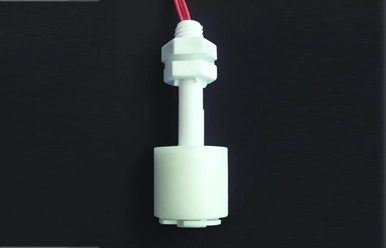

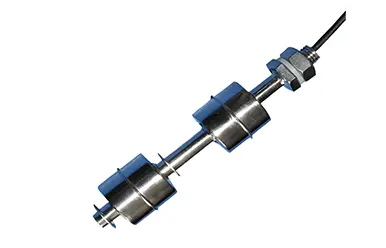

A liquid level sensor, often referred to as a float switch, typically comprises two main components: a stem and a float. The stem is fixed to the top or bottom of a tank and contains one or more hermetically sealed reed switches, with electrical wires routed outside the container. The float, which is doughnut-shaped or cylindrical and moves freely along the stem, rises and falls with the liquid level. When the float aligns magnetically with a reed switch inside the stem, it actuates the switch, sending an electrical signal.

These reed switch-based sensors are available in normally open (NO) or normally closed (NC) configurations and can be installed vertically or horizontally. To suit various application needs, multi-level and continuous level sensing options are also offered. Common industries for these sensors include aquariums, HVAC, medical, marine, wastewater treatment, chemical processing, breweries, wineries, and bioprocessing.

Liquid level sensors utilize various technologies and designs to cater to different needs. Here are some of the most commonly used types in water level sensor switch provided by BST Sensor:

Vertical Liquid Level Sensor: Installed vertically, these magnetic float switch sensors are ideal for tank monitoring. They use magnetic floats that rise and fall with the liquid, providing highly accurate measurements.

Horizontal Liquid Level Sensor: Mounted on the side of tanks, these level switch sensors detect liquid levels at predetermined points, making them perfect for preventing overflows or maintaining specific levels.

Multi Liquid Level Sensor: These level liquid sensors monitor multiple liquid levels within a single container, making them suitable for complex processes requiring multi-stage monitoring.

Continuous Level Sensor: Designed for real-time, uninterrupted monitoring, these sensors deliver continuous data for critical applications that demand constant oversight.

Magnetic Floats: Often integrated into other sensor types, magnetic floats operate on buoyancy principles and magnetic interaction, ensuring reliable and precise readings.

Modern magnetic float level sensors are equipped with advanced features to meet the rigorous demands of industrial and commercial applications:

High Accuracy: These liquid water level sensors provide precise measurements, essential for maintaining tight process control.

Durability: Built to withstand harsh conditions, they resist corrosion, extreme temperatures, and challenging environments.

Versatility: Adaptable to various liquids, such as water, chemicals, and oils, liquid level sensors serve a wide range of industries.

Non-Contact Measurement: Many models offer non-contact measurement options, reducing contamination risks and lowering maintenance requirements.

Enhanced Safety: By preventing overflows, leaks, and other hazards, this magnetic float sensor for water level controller improves workplace safety and environmental protection.

Cost Savings: Accurate measurements minimize waste and improve process efficiency, resulting in lower operational costs.

Regulatory Compliance: Liquid level sensors ensure adherence to industry standards, making compliance with safety and environmental regulations easier.

Real-Time Monitoring: Continuous monitoring provides real-time data for better process control and informed decision-making.

Liquid level sensors play a crucial role in various applications across multiple industries. In home appliances like washing machines, dishwashers, and water purifiers, these sensors ensure efficient water usage, prevent overflows, and optimize operation. In industrial settings, they are used to monitor storage tanks, chemical processing equipment, and lubrication systems, enhancing process efficiency and safety. In the transportation sector, liquid level sensors track fuel, oil, and coolant levels in vehicles, ships, and airplanes, preventing breakdowns and ensuring reliable performance. They are also vital in automotive systems for monitoring washer fluid reservoirs and coolant systems. In safety applications, such as fire suppression systems, these sensors maintain proper liquid levels to ensure readiness during emergencies. Additionally, in HVAC systems, they monitor refrigerant and condensate levels, promoting energy efficiency and preventing leaks. In laboratories and research facilities, liquid level sensors provide accurate measurements essential for experiments, quality control, and R&D processes.

The different kinds of liquid level switches include: Optical, Capacitive, Conductive, Diaphragm, Float.

The stem of liquid level sensor has reed switch, and outside of the stem, there is a float. The float rises and falls with the liquid level, once the float reaches the preset point, the level sensor will be triggered.

Yes, a wifi or BLE device can be connected to the liquid level sensor so that the signal can be wireless connected.