Inductors, often referred to as coils, are essential components in electrical circuits, designed to store energy within a magnetic field. These components come in two primary types: air-core and iron-core inductors, each distinguished by the material used in their core. This article explores the differences between these inductor types, their performance characteristics, and their suitability for various applications, providing insights to help select the appropriate inductor for specific circuit requirements.

Air-core inductors feature a non-magnetic core, typically constructed from materials such as plastic or ceramic, which serve as insulators. These inductors are characterized by their low inductance values, making them particularly suitable for high-frequency circuits. The absence of a magnetic core reduces susceptibility to distortion, ensuring greater stability at high frequencies. This makes air-core inductors a preferred choice for applications where maintaining signal integrity in high-frequency environments is critical, such as in radio frequency (RF) circuits or communication systems.

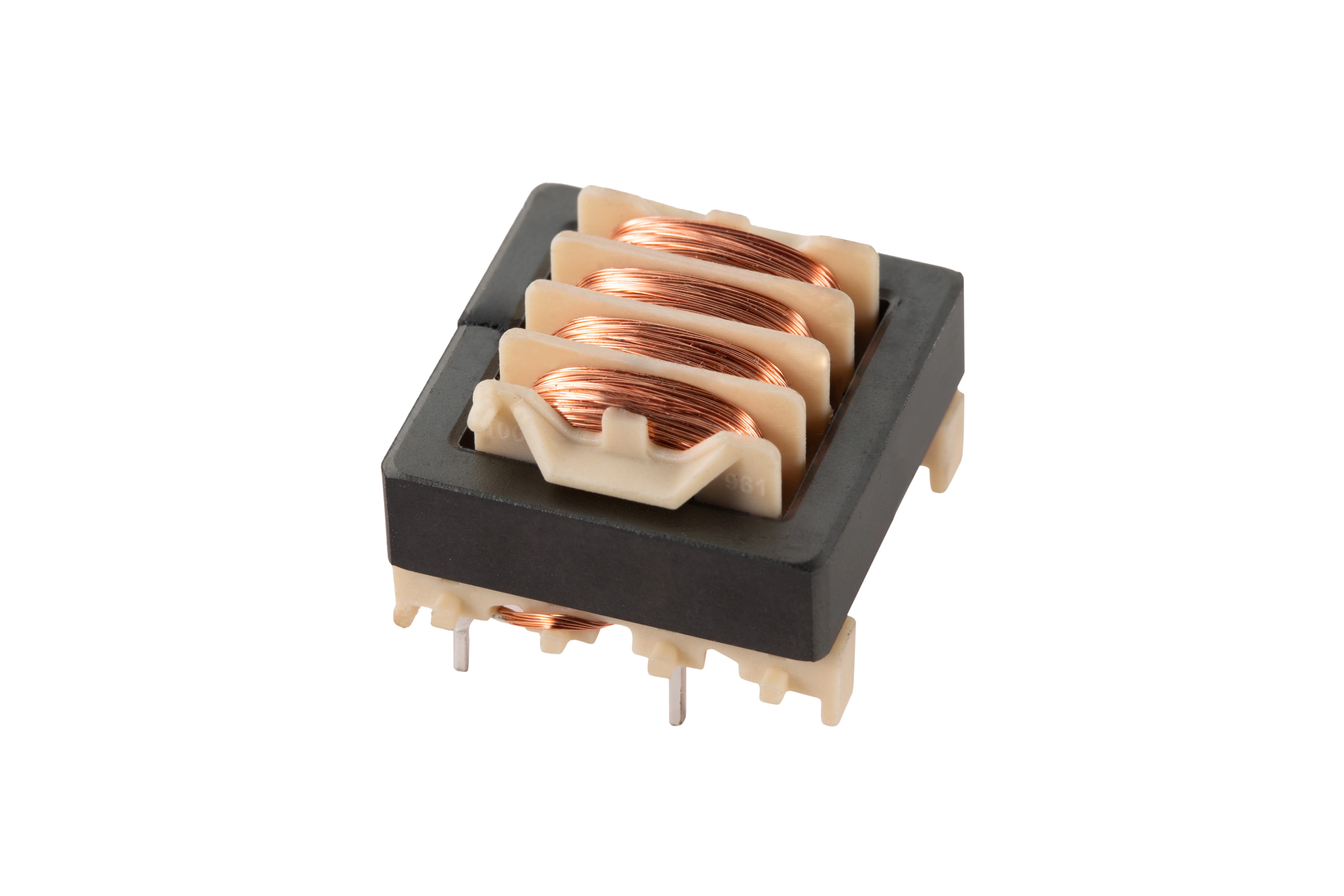

In contrast, iron-core inductors incorporate a magnetic core, often made of iron, ferrite, or powdered iron, which significantly enhances their inductance. This higher inductance makes them ideal for low-frequency circuits, where they can effectively manage changes in current and voltage. The magnetic core increases the inductor's ability to store energy by creating a stronger magnetic field, but it also introduces potential drawbacks, such as increased sensitivity to electrical changes and losses due to hysteresis and eddy currents, which can reduce efficiency in certain scenarios.

The primary distinction between air-core and iron-core inductors lies in their core materials, which directly influence their inductance and performance. Air-core inductors, with their non-magnetic cores, offer lower inductance but excel in high-frequency applications due to their stability and minimal distortion. They avoid losses associated with magnetic cores, such as hysteresis and eddy currents, making them more efficient in high-frequency settings. However, their lower inductance limits their energy storage capacity. Iron-core inductors, with their high magnetic permeability, produce stronger magnetic fields, resulting in significantly higher inductance, which is advantageous for low-frequency applications like power supplies or audio equipment. The trade-off is the potential for energy losses due to the magnetic core's properties, which can reduce efficiency, particularly at higher frequencies. Additionally, air-core inductors tend to be more expensive due to their specialized materials and construction, while iron-core inductors are more cost-effective and widely used in low-frequency applications where high inductance is prioritized.

Selecting between air-core and iron-core inductors depends on the specific requirements of the circuit and the desired performance outcomes. Air-core inductors are ideal for high-frequency applications where stability and low distortion are critical, despite their higher cost and lower inductance. Conversely, iron-core inductors are better suited for low-frequency applications requiring high inductance and cost efficiency, though designers must account for potential losses due to hysteresis and eddy currents. By carefully evaluating the operating frequency, inductance needs, and efficiency goals, engineers can choose the inductor type that best aligns with their application's demands, ensuring optimal circuit performance.

BST Sensor is a leading manufacturer specializing in high-quality magnetic sensing and switching solutions, including reed sensors, flow switches, liquid level sensors, temperature sensors, and custom magnetic components. With decades of expertise in innovative sensor technology, BST serves diverse industries such as automotive, industrial automation, HVAC, home appliances, and security systems. The company emphasizes precision, durability, and customization, offering tailored solutions with certifications like ISO 9001, TS16949, and AEC-Q200. Through its strong R&D capabilities and commitment to quality, BST Sensor delivers reliable, high-performance sensing solutions for a wide range of applications worldwide.