Transformers are indispensable components in electrical and electronic systems, harnessing the principles of electromagnetism discovered by Michael Faraday to transfer energy efficiently. From powering homes to enabling cutting-edge electronics, transformers come in various types, each tailored to specific applications. This guide explores the diverse categories of transformers—based on voltage level, core material, winding arrangement, and usage—highlighting their construction, applications, and key considerations. Whether you're an engineer, hobbyist, or curious learner, this article will help you understand how to select the right transformer for your project while ensuring safety and performance.

A transformer is an electromagnetic device that transfers electrical energy between two or more circuits through electromagnetic induction. It consists of primary and secondary windings wrapped around a core, with no direct electrical connection between the coils. By inducing a magnetic flux, transformers can step up or step down voltage levels, isolate circuits, or match impedances, making them essential in power distribution, electronics, and communication systems.

Choosing the right transformer is critical for optimizing circuit performance, efficiency, and safety. Factors such as voltage requirements, frequency, core material, and application environment influence the choice. Incorrect selection can lead to energy losses, overheating, or equipment failure. Understanding the different transformer types ensures you align their specifications with your project's needs.

Step-down transformers reduce the primary voltage to a lower secondary voltage, achieved by having more primary windings than secondary, resulting in a winding ratio greater than 1. In electronics, they convert high voltages, like 230V AC from power outlets, to lower levels such as 5V or 12V for devices like chargers and power adapters. In electrical systems, step-down transformers are vital in distribution networks, lowering high-voltage lines to safe household levels (e.g., 110V or 230V), minimizing transmission losses over long distances.

Step-up transformers increase the primary voltage to a higher secondary voltage, with fewer primary windings than secondary, yielding a winding ratio less than 1. They are used in electronics for applications like voltage stabilizers and inverters, converting low voltages to higher levels. In power distribution, step-up transformers elevate generator output voltages for efficient long-distance transmission, reducing energy losses by minimizing current flow.

Isolation transformers maintain equal primary and secondary voltages with a 1:1 winding ratio, providing no voltage conversion. Their primary function is to isolate the primary and secondary circuits, enhancing safety by preventing direct electrical connections and reducing noise transfer. They are widely used in sensitive equipment, such as medical devices and audio systems, to protect against electrical shocks and ensure clean signal transmission.

Iron-core transformers use laminated soft iron plates as the core, offering high magnetic permeability and efficient flux linkage. The thin plates, often shaped like E, I, or U, reduce eddy current losses, and the coils are wound around a former mounted on the core. These transformers are heavy but highly efficient, making them ideal for low-frequency power applications like distribution transformers and industrial equipment.

Ferrite-core transformers employ ceramic cores made from iron oxide and metal oxides, known for high permeability and low losses at high frequencies. Commonly shaped as E-cores, they are lightweight and used in electronics for switch-mode power supplies (SMPS), RF circuits, and inverters. Their efficiency in the kHz to MHz range makes them perfect for compact, high-frequency applications.

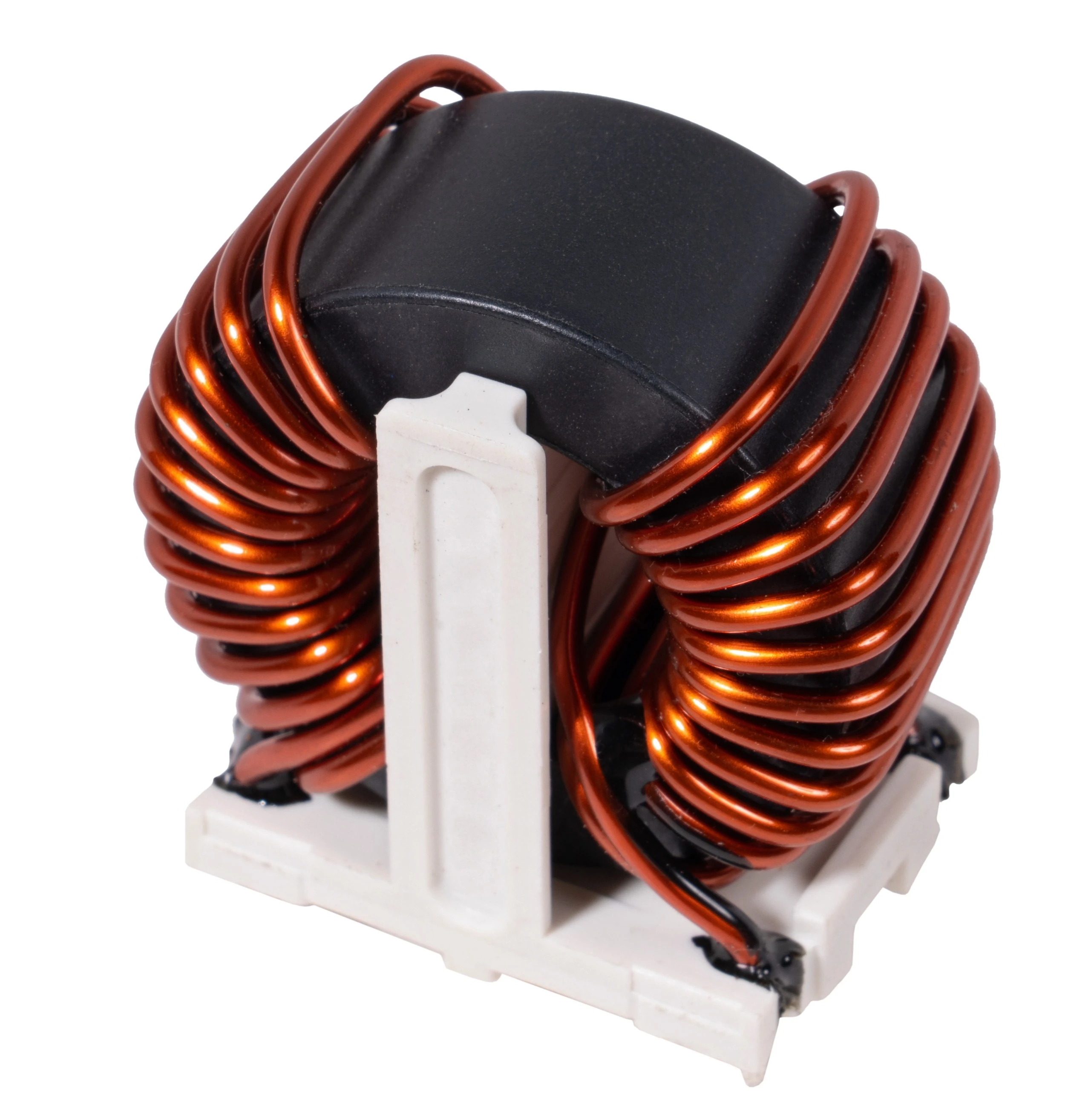

Toroidal-core transformers feature a ring-shaped core, typically made of iron or ferrite, which minimizes leakage inductance and maximizes efficiency due to short windings. Their compact, lightweight design and high inductance make them suitable for audio equipment, medical devices, and power supplies where low noise and space savings are critical.

Air-core transformers lack a physical magnetic core, using air as the flux medium, resulting in low mutual inductance but minimal weight. They are used in high-frequency applications like RF circuits and wireless charging systems, where the primary coil generates a magnetic field to induce current in a secondary coil. Their lightweight nature suits portable electronics, though they are less efficient than magnetic-core transformers.

Auto-winding transformers, or autotransformers, use a single coil for both primary and secondary functions, with a movable center-tapped node to adjust the voltage ratio. Known as VARIACs, they provide variable AC output from a fixed input, used in laboratories, voltage stabilizers, and power transmission systems. Variants with fixed tappings, selected via relays, are common in UPS and inverters, offering flexible voltage outputs without moving parts.

Power transformers are large-scale devices that bridge power generators and distribution grids, converting low-voltage, high-current outputs to high-voltage, low-current for efficient transmission. Available in small (30 kVA to 7000 kVA), medium (up to 50-100 MVA), and large (over 100 MVA) ratings, they feature oil-filled insulation and robust cooling systems. Typically three-phase, they are more efficient but costlier than single-phase units, used in substations and industrial settings.

Measurement transformers, or instrument transformers, scale down high voltages and currents for safe measurement. Current transformers (CTs) reduce current to measurable levels, while potential transformers (PTs) step down voltages. They isolate instruments from high-voltage lines, enabling accurate monitoring of phase, current, and voltage in power systems.

Distribution transformers step down high grid voltages to end-user levels (110V or 230V), available as single- or three-phase units. Rated below 200 kVA, they use dry or liquid-immersed insulation and laminated steel cores, often C-shaped. Mounted on poles, pads, or in chambers, they are the final stage in power delivery, ensuring safe and reliable electricity for homes and businesses.

Pulse transformers, typically PCB-mounted, generate consistent electrical pulses for digital circuits, providing isolation between primary and secondary windings. They are used in logic gates and drivers, requiring low leakage and stray capacitance for reliable pulse transmission in isolated environments.

Audio output transformers match impedance between amplifiers and loudspeakers, ensuring efficient power transfer in audio systems. With multiple or center-tapped windings, they balance circuits for clear sound reproduction, commonly used in high-fidelity audio equipment.

In electronics, current transformers (CTs) measure AC current with minimal primary turns, often using a power line as a single-turn primary through a toroidal core. Voltage transformers, essentially step-down units, reduce voltages to levels suitable for microcontrollers, popular in DIY projects like the ZMPT101B.

RF transformers, designed for radio and communication systems, use ferrite or powdered iron cores to maintain impedance matching and signal integrity at high frequencies. They minimize loss and distortion, supporting efficient energy transfer in antennas and transmission lines.

Variacs feature a single winding with a movable contact for smooth voltage adjustment, used in labs, lighting dimmers, and motor control. They offer flexibility from zero to above input voltage, ideal for testing and variable power applications.

Instrument transformers, encompassing CTs and PTs, ensure safe measurement of high voltages and currents by isolating instruments, widely used in power and electronic systems for accurate monitoring.

Resonant transformers operate at resonant frequencies, leveraging inductance and capacitance for efficient energy transfer in radio transmitters and high-frequency power supplies.

Matching transformers optimize power transfer by aligning source and load impedances, used in audio systems for amplifiers and speakers and in RF circuits for antennas.

Toroidal transformers, with ring-shaped cores, provide low leakage, high efficiency, and compact size, ideal for power supplies and audio equipment requiring minimal noise.

Three-phase transformers, configured in delta or wye, handle high-power transmission and industrial applications, offering efficiency for large-scale electrical systems.

Rectifier transformers, designed for high peak currents, support DC power supplies and industrial applications, often featuring multiple secondary windings.

Evaluate voltage, frequency, and power needs. High-frequency electronics favor ferrite or air-core transformers, while power applications suit iron-core or toroidal types. Ensure the transformer's ratings match your circuit's demands.

Consider core losses, insulation, and cooling. Ferrite and toroidal transformers offer high efficiency at high frequencies, while iron-core types excel in low-frequency power systems. Always follow safety protocols during design and installation.

Balance size, weight, and budget. Toroidal and ferrite transformers save space, while iron-core units are cost-effective for high-power needs. Check availability to avoid delays.

Transformers are versatile components powering everything from household appliances to advanced communication systems. By understanding their types—based on voltage, core material, winding, and usage—you can select the ideal transformer for your application. Whether you're designing a compact SMPS or a robust power distribution system, this guide equips you with the knowledge to make informed decisions, enhancing efficiency and reliability in your projects.